Page 1 - Combined_105_OCR

P. 1

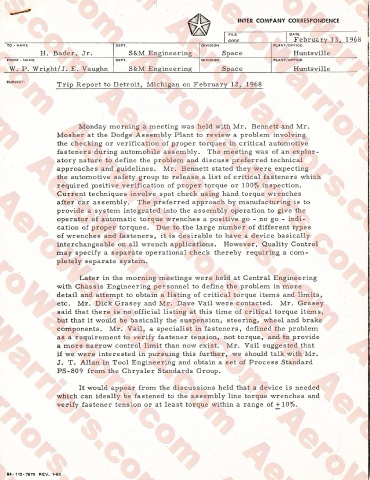

INTER COMPANY CORRESPONDENCE

DATE

13, 1968

TO - NAME DEPT. DIVISION PLANT/OFFICE

H. Bader,, Jr. S&M Engineering Space Huntsville

FROM - NAME DEPT. DIVISION PLANT/OFFICE

W. P. Wright/J. E. Vaughn S&M Engineering Space Huntsville

SUBJECT:

Trip Report to Detroit, Michigan on February 12, 1968

Monday morning a meeting was held with Mr. Bennett and Mr.

Mosher at the Dodge Assembly Plant to review a problem involving

the checking or verification of proper torques in critical automotive

fasteners during automobile assembly. The meeting was of an explor

atory nature to define the problem and discuss preferred technical

approaches and guidelines. Mr. Bennett stated they were expecting

the automotive safety group to release a list of critical fasteners which

required positive verification of proper torque or 100% inspection.

Current techniques involve spot check using hand torque wrenches

after car assembly. The preferred approach by manufacturing is to

provide a system integrated into the assembly operation to give the

operator of automatic torque wrenches a positive go - no go - indi

cation of proper torques. Due to the large number of different types

of wrenches and fasteners, it is desirable to have a device basically

interchangeable on all wrench applications. However, Quality Control

may specify a separate operational check thereby requiring a com

pletely separate system.

Later in the morning meetings were held at Central Engineering

with Chassis Engineering personnel to define the problem in more

detail and attempt to obtain a listing of critical torque items and limits,

etc. Mr. Dick Grasey and Mr. Dave Vail were contacted. Mr. Grasey

said that there is no official listing at this time of critical torque items,

but that it would be basically the suspension, steering, wheel and brake

components. Mr. Vail, a specialist in fasteners, defined the problem

as a requirement to verify fastener tension, not torque, and to provide

a more narrow control limit than now exist. Mr. Vail suggested that

if we were interested in pursuing this further, we should talk with Mr.

J. T. Allan in Tool Engineering and obtain a set of Process Standard

PS-809 from the Chrysler Standards Group.

It would appear from the discussions held that a device is needed

which can ideally be fastened to the assembly line torque wrenches and

verify fastener tension or at least torque within a range of + 10%.

84- 110-7879 REV. 1-63