Page 2 - Combined_2_OCR

P. 2

NEW IDEAS

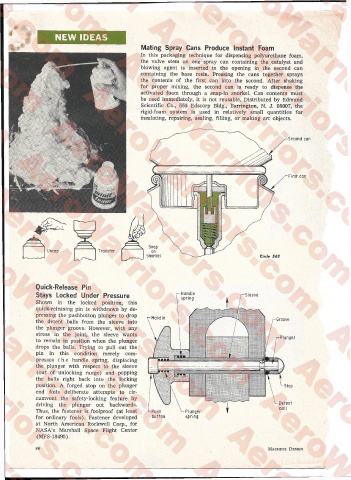

Mating Spray Cans Produce Instant Foam

In this packaging technique for dispensing polyurethane foam,

the valve stem on one spray can containing the catalyst and

blowing agent is inserted in the opening in the second can

containing the base resin. Pressing the cans together sprays

the contents of the first can into the second. After shaking

for proper mixing, the second can is ready to dispense the

activated foam through a snap-in snorkel. Can contents must

<% be used immediately, it is not reusable. Distributed by Edmund

Scientific Co., 555 Edscorp Bldg., Barrington, N. J. 08007, the

rigid-foam system is used in relatively small quantities for

insulating, repairing, sealing, filling, or making art objects.

Second can

Transfer

Snorkel Circle 563

Quick-Release Pin

Stays Locked Under Pressure

Shown in the locked position, this

quick-releasing pin is withdrawn by de

pressing the pushbutton plunger to drop

the detent balls from the sleeve into

the plunger groove. However, with any

stress in the joint, the sleeve wants

to remain in position when the plunger

drops the balls. Trying to pull out the

pin in this condition merely com

presses the handle spring, displacing

the plunger with respect to the sleeve

(out of unlocking range) and popping

the balls right back into the locking

position. A forged stop on the plunger

end foils deliberate attempts to cir

cumvent the safety-locking feature by

driving the plunger out backwards.

Thus, the fastener is foolproof (at least

for ordinary fools). Fastener developed

at North American Rockwell Corp., for

NASA’s Marshall Space Flight Center

(MFS-18495).

86 Machine Design