Page 1 - Combined_134_OCR

P. 1

FLYINi

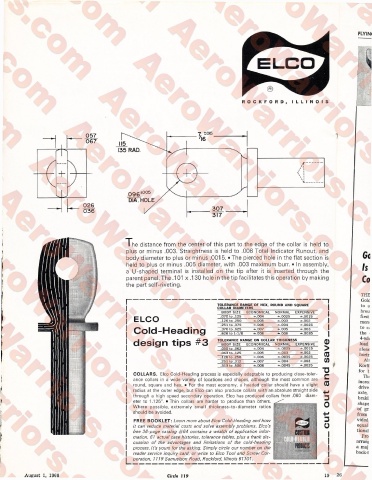

057 7 ±OI5

ZI6

067

II5

I35 RAD.

K.

O96±005

DIA.HOLE

026

036 307

317

The distance from the center of this part to the edge of the collar is held to

plus or minus .003. Straightness is held to .008 Total Indicator Runout, and

body diameter to plus or minus .001 5. ■ The pierced hole in the flat section is Gc

held to plus or minus .005 diameter, with .003 maximum burr. ■ In assembly,

a U-shaped terminal is installed on the tip after it is inserted through the

parent panel. The .101 x .1 30 hole in the tip facilitates this operation by making Co

the part self-riveting.

THE

Golc

TOLERANCE RANGE OF HEX, ROUND AND SQUARE to u

COLLAR DIAMETERS

BODY SIZE ECONOMICAL NORMAL EXPENSIVE brou

ELCO .070 to .125 ±.004 ±.0025 ±.0015 first

±.005

±.003

±.002

.126 to .250

mers

.251 to .375 ±.006 ±.004 ±.0025 to ci

±.003

Cold-Heading .376 to .625 ±.007 ±.005 ±.0035 the <

±.006

±.008

.626 to 1-1/8

4-wh

TOLERANCE RANGE ON COLLAR THICKNESS

design tips #3 BODY SIZE ECONOMICAL NORMAL EXPENSIVE load

.030 to .062 ±.004 ±.0025 ±.0015 alone

.063 to .125 ±.005 ±.003 ±.002 horiz

.126 to .250 ±.006 ±.0035 ±.0025

.251 to .312 ±.007 ±.004 ±.003 Alt

.313 to .500 ±.008 ±.0045 ±.0035 Korfi

for t

COLLARS. Elco Cold-Heading process is especially adaptable to producing close-toler Tlx

ance collars in a wide variety of locations and shapes, although the most common are increi

round, square and hex. ■ For the most economy, a headed collar should have a slight drive

radius at the outer edge, but Elco can also produce collars with an absolute straight side axle,

through a high speed secondary operation. Elco has produced collars from .060 diam braki:

eter to 1.125". ■ Thin collars are harder to produce than others. shape

Where possible, extremely small thickness-to-diameter ratios

should be avoided. of gr

from

FREE BOOKLET: Learn more about Elco Cold-Heading and how vided

it can reduce material costs and solve assembly problems. Elco’s equal

free 36-page catalog #64 contains a wealth of application infor tional

mation, 61 actual case histories, tolerance tables, plus a frank dis Fro

cussion of the advantages and limitations of the cold-heading arranj

process. It's yours for the asking. Simply circle our number on the a maj

reader service inquiry card, or write to Elco Tool and Screw Cor back-t

poration. 1119 Samuelson Hoad. Rockford. Illinois 61101.

August 1, 1968 Circle 119 19 26