Page 9 - Combined_134_OCR

P. 9

FLYING CARS

Photo courtesy Wynn Oil Co.

Dragsters:

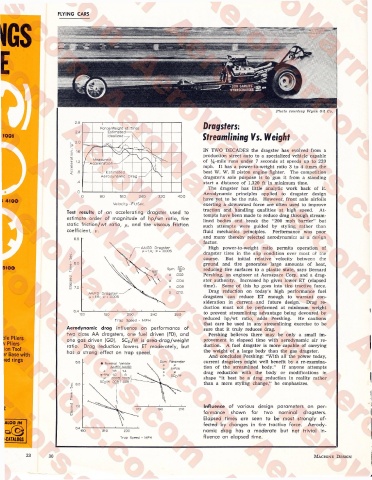

Force/Weight of Tires

?4 Estimated

Idealized- Streamlining Vs. Weight

2.0 IN TWO DECADES the dragster has evolved from a

Acceleration ~’g ' 1.6 cceleration----- production street auto to a specialized vehicle capable

Measured /

of %-mile runs under 7 seconds at speeds up to 220

1.2

mph. It has a power-to-weight ratio 3 to 4 times the

I I

.8

-------' Estimated -1—

Aerodynamic Drag best W. W. II piston engine fighter. The competition

dragster’s sole purpose is to gun it from a standing

.4 start a distance of 1,320 ft in minimum time.

The dragster has little analytic work back of it.

0 Aerodynamic principles applied to dragster design

0 80 160 240 320 400

have yet to be the rule. However, front axle airfoils

Velocity - Ft./Sec. exerting a downward force are often used to improve

Test results of an accelerating dragster used to traction and handling qualities at high speed. At

tempts have been made to reduce drag through stream

estimate order of magnitude of hp/wt ratio, tire lined bodies and break the “200 mph barrier” but

static friction/wt ratio, and tire viscous friction such attempts were guided by styling rather than

coefficient, v. fluid mechanics principles. Performance was poor

and many thereby rejected aerodynamics as a design

8.8 I-

factor.

AA/GD Dragster High power-to-weight ratio permits operation of

H = 1.4; P = 0005 dragster tires in the slip condition over most of tne

Time-Sec. 8.0 Sym. 5Cd ground and tire generates large amounts of heat,

course. But initial relative velocity between the

reducing tire surfaces to a plastic state, says Bernard

O 002

Elapsed A 004 Pershing, an engineer at Aerospace Corp, and a drag

ster authority. Increased hp gives lower ET (elapsed

time). Some of this hp goes into tire tractive force.

□ 008

7.2

Drag reduction on today’s high performance fuel

AA/FD Dragster

g ■ 1.8; v = .0005 dragsters can reduce ET enough to warrant con

sideration in current and future design. Drag re

duction must not be performed at minimum weight

6.4 ----------1----------1--------- 1--------- 1--------- 1--------- 1--------- 1----------1------

120 160 200 240 280 to prevent streamlining advantage being devoured by

reduced hp/wt ratio, adds Pershing. He cautions

Trap Speed - MPH

that care be used in any streamlining exercise to be

Aerodynamic drag influence on performance of sure that it truly reduces drag.

two class AA dragsters, one fuel driven (FD), and Pershing believes there may be only a small im

one gas driven (GD). SCD/W is area-drag/weight provement in elapsed time with aerodynamic air re

ratio. Drag reduction lowers ET moderately, but duction. A fuel dragster is more capable of carrying

has a strong effect on trap speed. the weight of a large body than the gas dragster.

And concludes Pershing: “With all the power today,

current dragsters might well benefit by a re-examina

tion of the streamlined body.” If anyone attempts

drag reduction with the body or modifications in

shape “it best be a drag reduction in reality rather

than a mere styling change,” he emphasizes.

Influence of various design parameters on per

formance shown for two nominal dragsters.

Elapsed times are seen to be most strongly af

fected by changes in tire tractive force. Aerody

namic drag has a moderate but not trivial in

Trap Speed - MPH fluence on elapsed time.

30 Machine Design