Page 6 - Combined_8_OCR

P. 6

Manual Manufacturing Chemists’ Association, Inc. Tolylene Diisocyanate

Sheet

SD-73

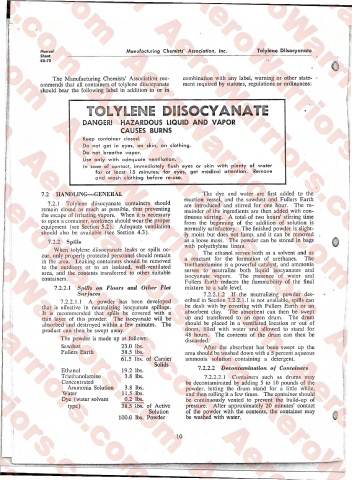

The Manufacturing Chemists’ Association rec combination with any label, warning or other state

ommends that all containers of tolylene diisocyanate ment required by statutes, regulations or ordinances:

should bear the following label in addition to or in

TOLYLENE DIISOCYANATE

DANGER! HAZARDOUS LIQUID AND VAPOR

CAUSES BURNS

Keep container closed.

Do not get in eyes, on skin, on clothing.

Do not breathe vapor.

Use only with adequate ventilation.

In case of contact, immediately flush eyes or skin with plenty of water

for at least 15 minutes; for eyes, get medical attention. Remove

and wash clothing before re-use.

7.2 HANDLING—GENERAL The dye and water are first added to the

reaction vessel, and the sawdust and Fullers Earth

7.2.1 Tolylene diisocyanate containers should are introduced and stirred for one hour. The re

remain closed as much as possible, thus preventing mainder of the ingredients are then added with con

the escape of irritating vapors. When it is necessary tinuous stirring. A total-of two hours’ stirring time

to open a container, workmen should wear the proper from the beginning of the addition of solution is

equipment (see Section 5.2). Adequate ventilation normally satisfactory. The finished powder is slight

should also be available (see Section 4.3). ly moist but does not lump, and it can be removed

7.2.2 Spills as a loose mass. The powder can be stored in bags o

with polyethylene liners.

When tolylene diisocyanate leaks or spills oc

The ethanol serves both as a solvent and as

cur, only properly protected personnel should remain a reactant for the formation of urethanes. The

in the area. Leaking containers should be removed

to the outdoors or to an isolated, well-ventilated triethanolamine is a powerful catalyst, and ammonia

area, and the contents transferred to other suitable serves to neutralize both liquid isocyanates and

containers. isocyanate vapors. The presence of water and

Fullers Earth reduces the flammability of the final

7.2.2.1 Spills on Floors and Other Flat mixture to a safe level.

Surfaces 7.2.2.1.2 If the neutralising powder des

7.2.2.1.1 A powder has been developed cribed in Section 7.2.2.1.1 is not available, spills can

that is effective in neutralizing isocyanate spillage. be dealt with by covering with Fullers Earth or an

It is recommended that spills be covered with a absorbent clay. The absorbent can then be swept

thin layer of this powder. The isocyanate will be up and transferred to an open drum. The drum

absorbed and destroyed within a few minutes. The should be placed in a ventilated location or out of

product can then be swept away. doors, filled with water and allowed to stand for

48 hours. The contents of the drum can then be

The powder is made up as follows:

discarded.

Sawdust 23.0 lbs. After the absorbent has been swept up the.

Fullers Earth 38.5 lbs. area should be washed down with a 5 percent aqueous

61.5 lbs. of Carrier ammonia solution containing a detergent.

Solids

Ethanol 19.2 lbs. 7.2.2.2 Decontamination of Containers

Triethanolamine 3.8 lbs. 7.2.2.2 A Containers such as drums may

Concentrated be decontaminated by adding 5 to 10 pounds of the

Ammonia Solution 3.8 lbs. powder, letting the drum stand for a little while,

Water 11.5 lbs. and then rolling it a few times. The container should

Dye (water solvant 0.2 lbs. be continuously vented to prevent the build-up of

type) 38.5 lbs. of Active pressure. After approximately 20 minutes’ contact

Solution of the powder with the contents, the container may

100.0 lbs. Powder be washed with water.

10