Page 6 - Combined_4_OCR

P. 6

ter the fresh air system of the proved cartridge respirator 5. After cessation of spraying, no

building. with a prefilter. person may enter the 50 foot zone

(e) Tempered makeup air is recom b) In spaces smaller than 2,500 or the enclosed space for at least

mended to avoid building nega square feet, all persons who 30 minutes unless wearing an ap

tive pressure and to improve enter the space must wear ap proved chemical cartridge respir

general room ventilation. proved air-supply respirators. ator, or unless mechanical venti

(f) In some cases, the process equip 4. The respirator air supply must be lation has been employed to

ment at which diisocyanate leaks from a source maintained and lo insure that isocyanate concentra

may occur is too extensive to be cated to provide clean respirable tions are reduced to levels below

enclosed by an exhaust hood. air.

In this event, mechanical exhaust

and supply ventilation of the en- —

tire room may be necessary.

(g) The exhaust systems should be

periodically cheeked to insure .<

their proper operation.

Construction and Insulating-1 n-Ptace

—Investigations conducted in both in

door and outdoor locations show that

there can be a serious isocyanate vapor

hazard not only to the insulating work

ers but to other workers who may be

in the vicinity. Those who follow the

insulators on the job can be affected—

the carpenters, electricians, and other

tradesmen. In an effort to control the

insulation workers’ exposure and mini

mize the hazard to others, our Occupa

tional Health Division, in cooperation

with representatives of the insulating

workers, contractors, and isocyanate

manufacturers, has developed certain

safeguards.

Spraying:

1. The spray operator and his helper

must wear an approved air-supply

respirator.

2. All other persons located within

50 feet of the sprayer must wear

approved air-supply respirators.

3. a) In spaces larger than 2,500

square feet and out-of-doors,

persons who enter the 50 foot

zone only intermittently or

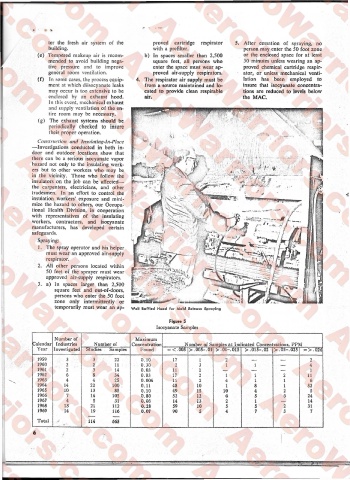

temporarily must wear an ap Well Baffjed Hood fer Mold Kelecsse Spraying

Figure 5

Isocyanate Samples

Number of Maximum

Calendar Industries Number of Concentration Number of Samples at Indicated Concentrations, PPM

Year Investigated Studies Samples Found = <.005 >.005-. 01 >.01-.015 >.015-.02 >.02-. 025 = >.026

1959 3 3 22 0.10 17 1 2 2

1960 2 2 11 0.30 2 3 1 1 4

1961 2 3 14 0.03 11 2 1

1962 6 8 34 0.83 17 2 1 1 2 11

1963 4 4 25 0.004 11 2 4 1 1 6

1964 14 22 100 . 0.11 48 10 1 8 1 32

1965 10 13 85 0.10 49 15 10 4 2 5

1966 7 14 105 0.80 52 12 6 5 6 24

1967 4 5 31 0.03 14 13 2 1 14

1968 13 21 112 0.28 59 10 5 5 2 31

1969 14 19 116 0.07 90 5 4 7 3 7

Total i 114 665