Page 6 - Combined_3_OCR

P. 6

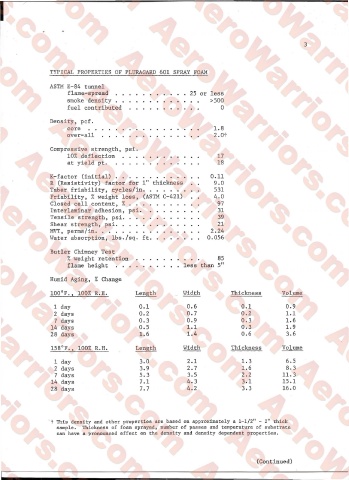

TYPICAL PROPERTIES OF PLURAGARD 601 SPRAY FOAM

ASTM E-84 tunnel

flame-spread 25 or less

smoke density . . . >500

fuel contributed o

Density, pcf.

core 1.8

over-all ............................................................... 2.0+

Compressive strength, psi.

10% deflection i— I

at yield pt i—l o o

K-factor (initial) o •

rd

rd

R (Resistivity) factor for 1" thickness . .

O .C

Taber friability, cycles/in UO O

r—I

Friability, % weight loss, (ASTM C-421) . .

O •

Closed cell content, % O'!

I"'*

Interlaminar adhesion, psi. . CO

rd

Tensile strength, psi CO Cb

Shear strength, psi 21

MVT, perms/in .24

Water absorption, Ibs./sq. ft. o 056

Butler Chimney Test

% weight retention 00 Ln

flame height less than Ln Z

Humid Aging, % Change

100 F., 100% R.H. Length Width Thickness Volume

day 0.1 0.6 0.1 0.9

T —I

bO days O • 0.7 O ♦ bo r-1 T —I

•

-L days O • CO 0.9 O • G O rd KD

•

H 5 days O • l U 1.1 O • co i—I Cb

•

28 days f —1 • 1.4 O • CO • KO

158°F., 100% R.H. Length Width Thickness Volume

day co o c m rd rd CO 6.5

H

o rd

N days co c m co VO 8.3

| uo CM 11.3

x days co LT) CM

JS days rd CO CO T~i 15.1

28 days r- CXI CO CO 16.0

+ This density and other properties are based on approximately a 1-1/2 - 2” thick

sample. Thickness of foam sprayed, number of passes and temperature of substrate

can have a pronounced effect on the density and density dependent properties.

(Continued)