Page 8 - Combined_3_OCR

P. 8

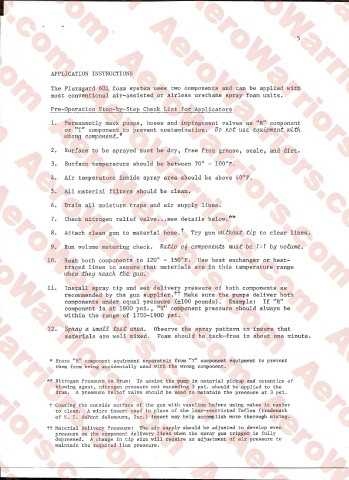

APPLICATION INSTRUCTIONS

The Pluragard 601 foam system uses two components and can be applied with

most conventional air-assisted or airless urethane spray foam units.

Pre-Operation Step-by-Step Check List for Applicators

1. Permanently mark pumps, hoses and impingement valves as "R" component

or "T" component to prevent contamination. Vo not LL6a aqutpmant Wtth

wttong component.*

2. Surface to be sprayed must be dry, free from grease, cale, and dirt.

Surface temperature should be between 70° - 100°F.

4. Air temperature inside spray area should be above 40 F.

5. All material filters should be clean.

6 • Drain all moisture traps and air supply lines.

7. Check nitrogen relief valve...see details below.**

Attach clean gun to material hose.^* Try gun wtthoat ttp to clear lines

9. Run volume metering check. Ratto o^ components must ba 1:1 by vohima.

10, Heat both components to 120° - 150 F. Use heat exchanger or heat-

traced lines to assure that materials are in this temperature rang

whan X/iey /teacA tha gun.

11. Install spray tip and set delivery pressure of both components as

recommended by the gun supplier.Make sure the pumps deliver both

components under equal pressure (±100 pounds). Example: If "R"

component is at 1800 psi., "T" component pressure should always be

within the range of 1700-1900 psi.

12. Sp^tay a SmaJUL tut (Vtact. Observe the spray pattern to insure that

materials are well mixed. Foam should be tack-free in about one minute

X- Store ”R” component equipment separately from ”T” component equipment to prevent

them from being accidentally used with the wrong component.

** Nitrogen Pressure on Drum: To assist the pump in material pickup and retention of

blowing agent, nitrogen pressure not exceeding 3 psi. should be applied to the

drum. A pressure relief valve should be used to maintain the pressure at 3 psi.

+ Coating the outside surface of the gun with vaseline before using makes it easier

to clean. A micro insert used in place of the less-restricted Teflon (trademark

of E. I. duPont deNemours, Inc.) insert may help accomplish more thorough mixing.

it Material Delivery Pressure: The air supply should be adjusted to develop even

pressure on the component delivery lines when the spray gun trigger is fully

depressed. A change in tip size will require an adjustment of air pressure to

maintain the required line pressure.