Page 7 - Combined_3_OCR

P. 7

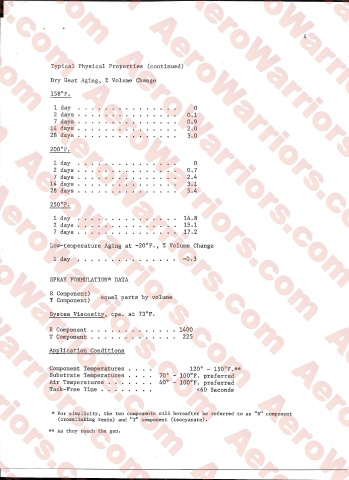

Typical Physical Properties (continued)

Dry Heat Aging, % Volume Change

158°Fo

day O

H

days . O r-i

(N

days . O

N

days . CN O

< r

vH

days . CO O

CN

co

200 F.

day O

rd

days O

(N

days M

days CO

i—

<■ I

28 days Ln 4>

250 F.

1 day................................. 14.8

2 days..........................................................................15.1

7 days........................ 17.2

Low-temperature Aging at -20°F.5 % Volume Change

1 day . -0.3

SPRAY FORMULATION* DATA

R Component)

equal parts by volume

T Component)

System Viscosity, cps. at 73°F.

R Component..........................................................1400

T Component..........................................................225

Application Conditions

Component Temperatures .... 120° - 150°F.**

Substrate Temperatures .... 70° - 100°F. preferred

Air Temperatures ....... 40° - 100°F. preferred

Tack-Free Time.................................. <60 Seconds

* For simplicity, the two components will hereafter be referred to as R component

(crosslinking resin) and "T" component (isocyanate).

** As they reach the gun.