Page 2 - Combined_133_OCR

P. 2

YOU BEEN TECHNICAL PAPERS

FOR... upon its frontal area, is approximately 0.04 CLARK B

^

About 1/2 of the drag of this body results fron

skin friction and 1/2 from pressure drag. One cut your ci

difference between this ideal shape and any

actual automobile body is that the ideal body your produ

is assumed to be suspended in mid-air, while

the automobile is supported by its four wheels

touching the ground. The addition of well- Standards Or

shielded wheels to the ideal body increases its hoice is varie

drag by a factor of about 3 or 4 to 0.15, or per 3rrous metals

haps slightly less. This value is realizable for lark fastener*

all but the most extreme automobile body f products, in

shapes. Modifications to this basic automobile ■y. We add str

shape by windshields and rough undersurfaces while holding c

SOR increase the drag to the value of about 0.45yor accura|e

CITY? A 15( AGITATOR SHAFT SEAL? that is generally realized today. ^kj||ed

gainst the The drag of automobiles is shown in com- ..

rings . . . Used in automatic laundries, this seal is molded parison to that of various ideal shapes, and the* your neare

ve fatigue to final dimensions. No machining of the intricate stributor.

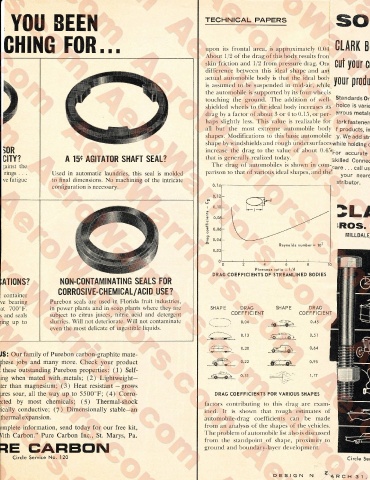

configuration is necessary. 0.14

— Cp

Drag co e fficie n ts MILLDALE.

1

Fineness ratio — l/d

DRAG COEFFICIENTS OF STREAMLINED BODIES

ATIONS? NON-CONTAMINATING SEALS FOR

CORROSIVE-CHEMICAL/ACID USE?

1 container

ve bearing Purebon seals are used in Florida fruit industries,

at 700°F. in power plants and in soap plants where they are SHAPE DRAG SHAPE DRAG

s and seals subject to citrus juices, nitric acid and detergent COEFFICIENT COEFF1CI

png up to slurries. Will not deteriorate. Will not contaminate ' o.O4 ,--- 0.45

even the most delicate of ingestible liquids.

1/ 0.13 0.51

0.20

c

JS: Our family of Purebon carbon-graphite mate-

|these jobs and many more. Check your product

: these outstanding Purebon properties: (1) Self

ing when mated with metals; (2) Lightweight—

[ter than magnesium; (3) Heat resistant — grows

pres soar, all the way up to 55OO°F; (4) Corro DRAG COEFFICIENTS FOR VARIOUS SHAPES

de ted by most chemicals; (5) Thermal-shock factors contributing to this drag are exam

rically conductive; (7) Dimensionally stable—an ined. It is shown that rough estimates of

thermal expansion. automobile-drag coefficients can be made

omplete information, send today for our free kit, from an analysis of the shapes of the vehicles.

The problem of automobile list also is discussed

Vith Carbon.” Pure Carbon Inc., St. Marys, Pa.

from the standpoint of shape, proximity to

ground and boundary-layer development.

Circle Service No. 120 Circle Ser

DESIGN N M R C H 3 1,